Fused Quartz Sand First Grade with Low Thermal Expansivity mainly used in Precision casting area. Main product specifications (0.5-0.2mesh,1-0 Mesh, 1-0.5mesh 40-70Mesh)

I.Characteristics

1. Near zero thermal expansion, extremely low thermal conductivity.

2. Excellent thermal stability.

3. High purity (the SiO2 content is above 99.8%).

4. Chemical properties are very stable.

5. General mechanical production, particle size for angle type.

II. Main Areas of Application

The Fused quartz grain mainly used in surface sand and surface powder for precision Casting .electronic sealing,paint,coating,Silican rubber,investment casting and high-grade electrical insulation and so on. High grade quartz nozzle,Filling materials including epoxy resin casting, electronic sealing,paint, coating,etc.

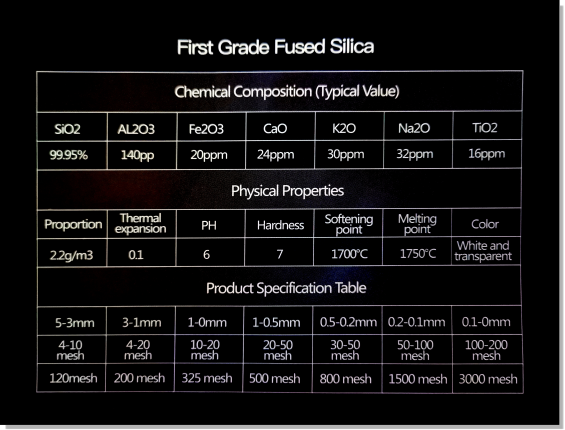

III. Basic Parameters

Bulk Density :2.2 g/m3

Hardness :7

Softening Point :1700°C

Melting Point :1750°C

Coefficient of Thermal Expansion :0.1

PH value :6

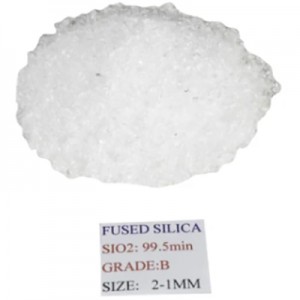

IV. Chemical Composition

| Guaranteed Value | Typical Values | |

| SiO2 | 99.7%min | 99.91% |

| Al2O3 | 500ppmmax | 360ppm |

| Fe2O3 | 500ppmmax | 150ppm |

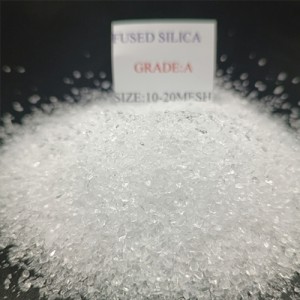

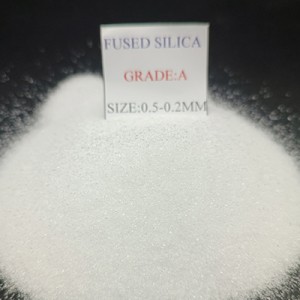

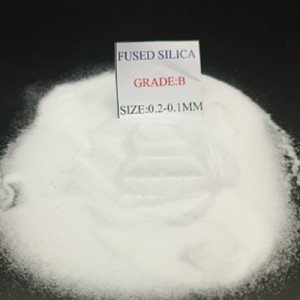

V. Availability Specifications

1. Block 0-60 mm

2. Granular

|

0.5-0.2mm |

5-3mm |

3-1mm |

1-0mm |

|

20-40 mesh |

4-10 mesh |

70-120 mesh |

0.1-0.2mm |

We are a quartz company which is one of the leading producing,grinding,crushing and exporting of quartz materials in Xuzhou China.

We have over 10 years production experience in precision casting and refractory materials.

We also offer a modified specification upon client requirement,Can be produced customized size and specifications to customer granularity requirements.

◆Products feature

1.With lower dielectric constant; Higher purity, better electrical insulation performance, high whiteness; Very low coefficient of thermal expansion;

2.More stable chemical properties,excellent acid and alkali resistance, corrosion resistance, weather resistance