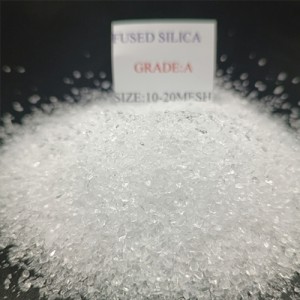

Fused Silica Sand

-

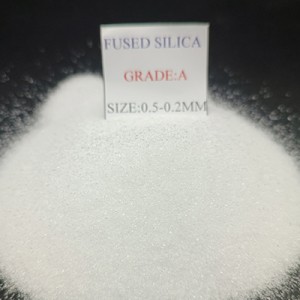

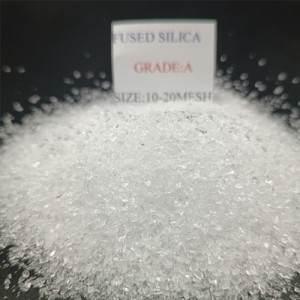

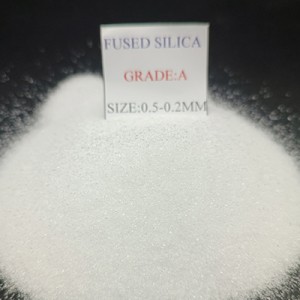

Fused Quartz Grain First Grade with High Purity Sio2 over 99.9% for Advanced Ceramics Products with Good Price (0.5-0.2 Mesh, 3-1Mesh,10-20Mesh)

Also Know as A grade with high purity with Sio2 around 99.7%-99.99%.

High purity quartz stone from Donghai and Xinyi area was selected as raw material. After pickling treatment, the crystalline silica was transformed into amorphous silica with a small amount of impurity at 1700ºC high temperature in the resistance furnace. After special mechanical processing, screening, iron removal after picking treatment of high purity quartz stones for the formation of blocks, particles and powder products

-

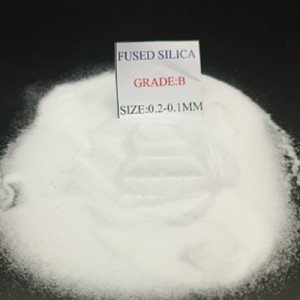

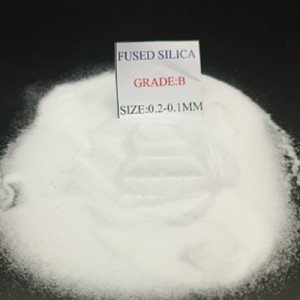

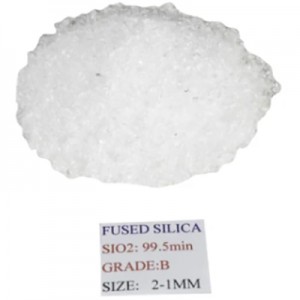

Fused Silica Sand Second Grade (also known as B grade),High Purity with Small black Dots,Mainly used fo Lining Materials,Silica bricks, Amorphous Refractories and Quartz Nozzles,etc.

Also called B grade Fused silica Sand with high purity Sio2 around 99.4%-99.7%.

Mainly used for lining materials Quartz nozzle, quartz crucible used in the steel industry, Shell making materials in precision casting, Multi-cavity honeycomb ceramics in environmental protection equipment, All kinds of crucible.

-

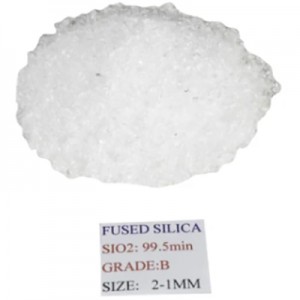

Fused Silica Sand Second Grade (also known as B grade)

Also Called Fused Quartz Grain Also called B grade Fused silica Sand with high purity Sio2 around 99.4%-99.7%,Characterized by Excellent air Permeability and easy Mold Filling.

For the shell made of Fused silica sand and powder instead of zirconium sand and powder , its aire permeability is obviously better than that of ordinary shells, and insufficient casting of small thin-wall castings and shrinkage, shrinkage catity and porosity of casting can be obviously improved.

-

High Grade Fused Quartz Products Used in Quartz Ceramic Crucible for Polycrystalline Silicon Ingot Casting Area

The ceramic products made of Fused silica are characterized by excellent thermal shock resistance, low thermal conductivity, small expansion coefficient, high temperature resistance, good thermal stability, corrosion resistance, etc. The products are not only resistant to sudden changes of temperature but also have excellent thermal insulation performance; the Fused silica materials are processed into lightweight thermal insulation products with a thermal insulation effect unmatched by other refractory lightweight thermal insulation products, which have been successfully applied to the metallurgy, building materials, chemical engineering, national defense, scientific research and other departments.

-

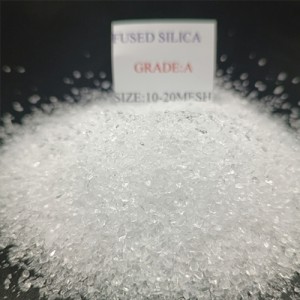

Fused Quartz Sand First Grade with Low Thermal Expansivity mainly used in Precision casting area. Main product specifications (0.5-0.2mesh,1-0 Mesh, 1-0.5mesh 40-70Mesh)

As the refractory materials for shell marketing of precision casting,Fused silica sand and powder have been widely used in the United States and Europe, and large number of experiments and production data shows that using high-purity Fused silica sand and powder for surface of shell making of precision casting has the their own advantages.

-

Top Grade Fused Quartz Particle First Grade with Excellent Shelling Performance For the Shell made .Main product specifications (50-100mesh,100-200 Mesh)

For the shell made of the Fused silica sand and powder instead of zirconium sand and powder, its shelling performance is significantly improved and it is more favorable to such chemical cleaning as alkali boiling and alkali explosion, thereby, reducing the cost of shell cleaning and improving the efficiency.