Fused quartz materials in the investment casting shell in developed countries are keep increasing year by year, especially in silica sol mold shell on surface layer has a lot of experience. Compare with the price and the usage of the zirconium material has made a great breakthrough, It’s an ideal engineering application materials in currently.

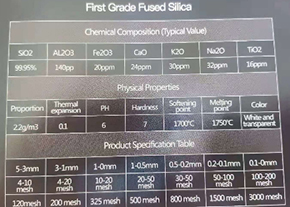

Fused quartz products are selected high quality silica raw materials [sio2>99%], melting in arc furnace or resistance furnace, at the high temperature of 1695-1720℃. Due to the high viscosity of sio2 melt, which is 10 ^ 7 Pa·s at 1900℃, it cannot be molded by casting method. After cooling, it is vitreous and can be used as raw material for fired or non-fired products. The Fused silica are characterized by excellent thermal shock resistance, low thermal conductivity, small expansion coefficient, high temperature resistance in ceramic products and refractory materials. So it has a very high thermal stability. Therefore, in the process of roasting and pouring molten quartz shell rarely breaks due to intense temperature, It’s an ideal materials in investment casting molding refractory, also can be used as surface layer or back layer coating refractory materials.

Our Fused silica Products are mainly used in precision casting, quartz ceramic roller in glass industry, refractory materials, ceramic raw materials, glass raw materials, epoxy resin casting, electronic sealing materials, electric light source, medical, casting, and other industries of the main raw materials, and also in paint, coating and other chemical industry ideal filling material.

The content of Sio2 purity for fused quartz: the Sio2 content of Fused silica A grade shall not be less than 99.95%, B grade shall not be less than 99.8%, and C grade shall not be less than 99%

Post time: Jan-13-2022