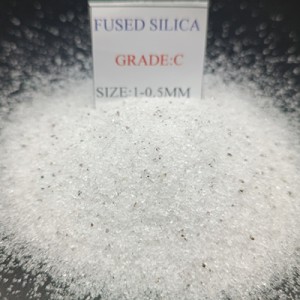

Fused Silica C Grade

I.Characteristics

1. Near zero thermal expansion, extremely low thermal conductivity.

2. Excellent thermal stability.

3. High purity (the SiO2 content is above 99%

4. Chemical properties are stable.

5. General mechanical production, particle size for angle type.

II. Main Areas of Application

High grade quartz nozzle,ceramic roller in glass industry.

High grade refractory materials

III. Basic Parameters

Bulk Density :2.2 g/m3

Hardness :7

Softening Point :1500°C

Melting Point :1580°C

Coefficient of Thermal Expansion :0.1

PH value :6

IV. Chemical Composition

| Guaranteed Value | Typical Values | |

| SiO2 | 99%min | 99.22% |

| Al2O3 | 500ppmmax | 360ppm |

| Fe2O3 | 500ppmmax | 150ppm |

1,The above physical parameters and chemical composition are based on the average value of the sample analysis test。

V. Availability Specifications

1. General size of Block: 0-50 mm,5-3mm,3-1mm

2. Granular(General size of Fused silica sand)

| 7um | 5-3mm | 3-1mm | 1-0mm |

| 20-50 mesh | 40-70 mesh | 70-120 mesh |

Can be produced according to customer granularity requirements

VI. Modes of packing

The general packing is Plastic woven bag 25KG and Craft paper bag 20KG/25K with Lined tonnage waterproof bags, The general jumbo bags we have 1000KG and 1250kg per jumbo bag.

VII. Terms of Payment

Normally we preferred the terms of payment with TT before shipment, we also agree the D/P at sight and Letter of Credit.

Our company has been committed to the research and improvement of the precision casting surface powder, we are now serving more than 100 domestic precision casting enterprises which all got the satisfied results.